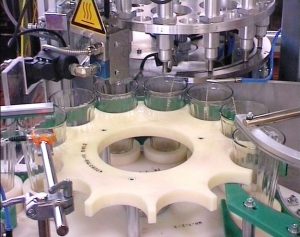

One of our many core competencies around candle manufacturing is the fully-automated wicking of different containers for a wide range of container candles.

There are a wide range of wick and wick sustaining plate pairs and glues of which nearly all can be processed by our machines. Customer-specific parts are nevertheless processed in bulk to make their production as effective as possible.

Often our wicking machines are part of a large filling line for glass candles or fragranced candles. More and more frequently, however, they are purchased individually to first automate the labor-intensive wicking process. Later when the quantities increase, the machine can be expanded to an entire line to combine it with an automated filling line, for example.

Tealight, cemetery light, glass candles, fragranced candles or other container candles, we do more than putting the wick into a container. Irrespective of whether an individual wick or multiple wicks are required, we have the wicking machine which is perfectly suitable for each case. Talk to us, we would be delighted to advise you.

Capacity: up to 7,000 pieces / hour due to new servo technique

Ø: up to 110 mm

Capacity: up to 2,200 pieces / hour

Ø: up to 110 mm

Insertion of wicks by means of biaxial robotism.

The containers are placed below the insertion ram.

It is possible to insert up to five wicks in one container.