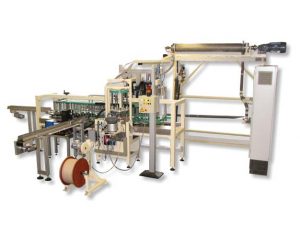

Pasty material is produced with a scraper cooler specifically developed by Herrhammer and is filled into a mixing tank. This distributes the material to multiple filler nozzles. Below this the containers run on a link belt into the filling and wicking center. An integrated wick inserting machine wicks the containers, whereby the wick is fixed in the center with two clamps at the top end. Opposite the supply point, the containers are filled by a heated multiple filler in clocked operation. The wicks are held in the center until the containers leave the filling area and are pushed out of the transport chain.

This technology ensures that you obtain perfectly pasty wax conforming to your specifications. Additional wick centering is not required. Nor does it have to be straightened or cut subsequently. Meaning that only a minimum of personnel is required for the entire plant.

As with all our plants customized solutions are our standard and are oriented towards your wishes with regard to output and product requirements. In all possible sizes and quantities – whether glass cup candles, plastic cup candles, cemetery lights, oil lights or colored fragranced candles.

Just contact us. It would be our pleasure to advise you on how to manufacture your candle in the most efficient manner possible.

Capacity:

up to 4,500 pieces / hour (with single coloured products weighing up to 150 g)

Design:

4 or 6-fold filler

Container dimensions:

Diameter: 50 – 120 mm

Height: 40 – 120 mm (210 mm possible at reduced speed)